BlueGuard Temperature Control, BlueGuard Temperature Controller, TEC Temperature Controller, Optical Module Bit Error Rate Testing, High and Low Temperature Cyclic Testing, Laser TEC Control, Optical Module Temperature Control, Precision Temperature Control Equipment, Bit Error Rate Temperature Stability, Optical Communication Test Temperature Control, Optical Module Aging Verification, Temperature Closed-Loop System, TEC Drive Temperature Control, Temperature Drift Suppression, High-Speed Optical Module Testing, Constant Temperature Control Platform, Optical Device Reliability Testing, Bidirectional Cooling and Heating Temperature Control, Temperature Control Accuracy, Temperature Curve Control, Optical Module Environmental Stress Testing, Optoelectronic Test Temperature Control

News

News

Update Time:2025-12-11 15:08:30

Update Time:2025-12-11 15:08:30 Views:

343

Views:

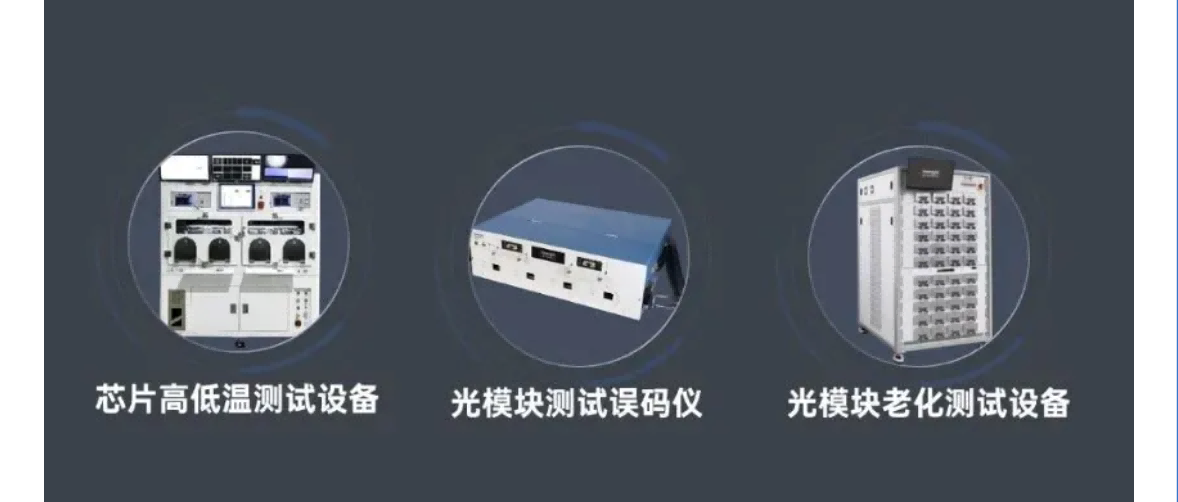

343 In the field of high-speed optical communication, 400G/800G/1.6T modules are core components of next-generation data centers and backbone networks, with extremely high requirements for reliability and bit error rate (BER). During the R&D, mass production testing, and verification stages of optical modules, BERT tests need to be performed on them at different ambient temperatures to evaluate the performance stability of the modules in high-temperature, normal-temperature, and low-temperature environments.

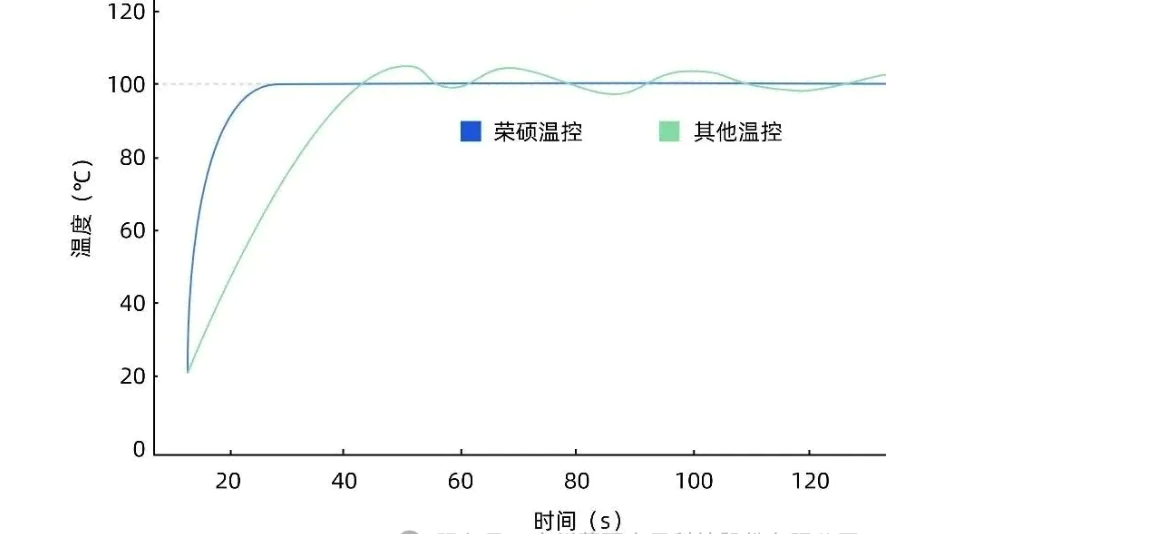

BlueGuard's TEC temperature control solution, with its advantages of high precision, fast response, bidirectional temperature control, and rapid customization, provides reliable high and low temperature environment simulation for optical module bit error rate testing. It significantly improves the accuracy and efficiency of optical module bit error rate testing, making it an ideal solution for temperature control systems in high-end optical communication test instruments.

Multi-channel independent temperature control: Supports independent temperature control for multiple channels, each with independent data acquisition and execution capabilities, ensuring no interference. Different target temperatures can be set for each channel, enabling simultaneous testing or differentiated verification of multiple modules. This significantly improves equipment utilization and testing flexibility, making it particularly suitable for multi-port parallel batch testing platforms for optical modules.

Available in 2/4/8 channels to meet diverse application scenarios, the BlueGuard TEC temperature controller series offers various specifications including 1, 2, 4, and 8 channels. It supports multiple communication methods such as TCP, RS485, and RS232, allowing for flexible integration into different control systems. The rich model configurations meet diverse needs, from single-point temperature control to multi-channel synchronous control.

01. Enhanced Testing Accuracy and Consistency

Utilizing the high-precision bidirectional temperature control technology of the BlueGuard TEC temperature controller, temperature stability is achieved better than ±0.1℃, effectively eliminating interference from ambient temperature fluctuations in bit error rate testing. Independent temperature control for each channel ensures the repeatability and consistency of test results for optical modules under different thermal environments, providing reliable temperature control assurance for high-speed optical module performance verification.

02. Improved Testing Efficiency and Automation

Supports multi-segment temperature control, allowing rapid switching between low, normal, and high temperature conditions. Fast heating and cooling speeds and short response times significantly shorten the testing cycle. Linkage with a host computer system via a communication interface automates the testing process, improving the overall testing efficiency of the production line.

03. High Integration and Operational Reliability

Integrates temperature acquisition, drive, and temperature control into one unit, simplifying wiring and system setup. Built-in multiple protection mechanisms, including over-temperature, over-current, open-circuit, and short-circuit protection, ensure stable and reliable operation during long-term continuous operation.

News

News

Email: 616526410@qq.com

Hotline: 13609016130

Address: Room 314, 3rd Floor, No. 9, Kemulang South Road, Tianhe District, Guangzhou

Filing No.: 粤ICP备2023092377号-3

Products

Temperature controller

Temperature controller  Temperature acquisition device

Temperature acquisition device  Industrial I/O Modules

Industrial I/O Modules  Industrial gateway

Industrial gateway  Power Regulator

Power Regulator Solutions

Semiconductor/Chip Industry

Semiconductor/Chip Industry  New energy/energy storage industry

New energy/energy storage industry  Optoelectronics/Display Industry

Optoelectronics/Display Industry  Rubber/Plastics Industry

Rubber/Plastics Industry  Biopharmaceutical industry

Biopharmaceutical industry  Industrial Furnaces/Thermal Industry

Industrial Furnaces/Thermal Industry  Mechanical Automation Industry

Mechanical Automation Industry  Other integrated applications

Other integrated applications Support

Manuals

Manuals

Tutorials

Tutorials

Tools

Tools

News

Company News

Company News  Exhibition News

Exhibition News  Media Information

Media Information